Ventless Cooking with Wells

Ventless cooking is one of the most important developments in foodservice as many operators face challenges with lack of space, lack of funds and impermanent locations. Ventless cooking has become a way for foodservice operators to do more with less. With a ventless hood system, operators can save money on expensive ductwork and maximize commercial kitchen space.

Why Go Ventless?

Ventless cooking is perfect for establishments that do not permit traditional ventilation, or where exhaust and duct work is too expensive. Ventless hood systems do not need to be vented outside and only work with electric food equipment, making it possible to cook in non-traditional locations. Additionally, ventless hoods provide a valuable tax benefit, since they depreciate quickly.

Ventless systems are best for:

- Where extensive duct work is cost prohibitive, like in high-rise buildings, stadiums and arenas.

- Places where traditional hood installations may be too difficult, like in malls, food courts and airports.

- Leased spaces. Ventless hood systems are portable.

- Kitchens where hood space is at capacity.

Wells Manufacturing leads the industry with ventless food equipment. They offer four different types of ventless systems, all made in America, and they have the largest selection of commercial electric equipment allowed underneath a ventless hood. The ventless possibilities with Wells are endless as all products have been tested and approved for higher temperature use over other brands.

Wells different ventless system types include:

- VCS (ventless cooking systems): Combined cooking equipment, ventilation and fire protection

- Universal Ventless Hoods and countertop: Allows for use of almost any commercial electric equipment

- Ventless fryers: High-production capacity fryers with ventilation

- Canopy Ventless Hoods: Ventless hoods with built-in filtration

Wells ventless system benefits:

- Hoods accommodate most electric equipment

- Fully self-contained ANSUL fire suppression

- Complies with local fire and mechanical codes

- Certified Type-1 hood, Wells qualifies for removal of grease-laden vapors

- 4-stage filtration exceeds NFPA 96 and Standard EPA 202 test methods for particulate emissions

- Wells ventless filters are easy to clean and will last for months, saving labor and time

- Sensing system continually monitors airflow to optimize performance and grease removal

- Optional duct adapter allows for exhausting or heated air (VCS units only)

- All heavy-duty, stainless steel construction for long life, durability and easy cleaning

Ventless Cooking Systems

The Wells VCS model has everything you need, together in one complete package. A completely self-contained unit with built-in electrical equipment, ANSUL fire suppression system and a ventless hood, giving operators the opportunity to set up shop in any well-ventilated area or expand production.

Each unit uses a single-point power connection with either a three-phase chord (provided) or single chord (customer provides). Each model is easy to set up and are plug-and-play after an ANSUL technician charges the system on site.

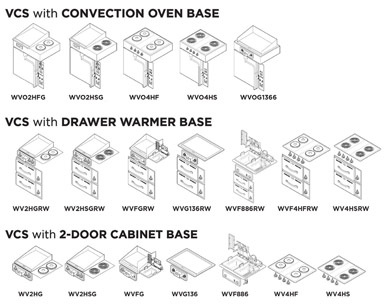

Available in three different base options: double drawer warmer, half-size oven or cabinet. The actual cooking surface of the base can be constructed to utilize a mix of hot plates, griddles, and deep fryers (on units with a cabinet or drawer base only) and come in 13 different configurations.

Wells VCS models are sturdy and practical with 4-stage filtration. They feature stainless-steel baffles, high-efficiency air filter and carbon/charcoal filters. They also include an interlock safeguard system in which the unit will not power up if filters are not in place. The system comes with warning light in the top of portion of all units.

The VCS model is great for large areas where under-utilized, but ventilated areas can become another generator of revenue. Because these ventless systems have a manual pull station for fire hazards, they are mobile and can be moved around. However, any local jurisdiction can override this model and require a remote pull station.

Universal Ventless Hoods

Wells Universal Ventless Hood Systems (WVU) allow operators to use almost any commercial electric cooking equipment underneath with no need for traditional Type-1 ventilation and duct work. Wells Universal Hoods do not require outside ventilation and have UL710B approved recirculation systems that are Type 1 compliant. Not only do they feature completely self-contained air filtration and fire-suppression systems, filtration reduces emissions below what is allowed in NFPA 96 and ANSI UL710B UL standards.

UVS models can create the perfect cook zone for instances where ventilation is needed, but the space and/or outlet for a conventional hood system isn’t possible. Wells ventless models are approved for use with higher temperature equipment than many of their competitors and require at least 108” of ceiling space for use.

Most ventless hood systems are approved for an oven max of 500°F and griddle max of 400°F. Wells systems are approved for higher temperatures – an oven max of 575°F and griddle max of 450°F.

These models are available in various sizes: the 96” is the largest available and comes in two different exhaust options (horizontal or vertical) and fits up to 100” of equipment underneath. After that is the 72”, which fits up to 72” of equipment underneath, and the 48”, which fits up to 50” of equipment. Electrically heated appliances are the only acceptable types for use under all Wells ventless products. The company offers a wide variety of cooking equipment already approved for operation under WVU hood models.

Countertop Ventless Systems

Wells Ventless Countertop Hoods are an ideal solution for chefs and operators who want to expand kitchen capabilities and revenue. These models can easily be placed on refrigerated bases, kitchen stands and countertops and come ANSUL ready. This means they are pre-plumbed for an external mounted fire suppression system that can be installed and charged by a licensed ANSUL agent.

Wells countertop systems can hold up to 31” of kitchen equipment and operators can mix and match items including countertop fryers, griddles and induction cooktops. This is the only system that does not come with an ANSUL fire suppression system, but one can be purchased at an additional cost. Once a fire suppression system is connected to this model, it cannot be moved.

Canopy Style Ventless Systems

Wells Canopy Style Hoods (WVC) are designed for use with convection and combi ovens or cook-and-hold warmers and general bakery ovens that are up to 46” wide. They come equipped with self-contained, 4-stage filtration and fire suppression connections for ANSUL or other third-party fire protection systems.

With these models, operators can only use forward facing, enclosed equipment appliances, including deck ovens, steamers, or proofer combis with electrical hookups only. They can be directly or indirectly vented and include an interlock safety system with warning lights that turn on when filters need replacing. They can be mounted on a wall or ceiling and are a practical and more economical solution for ventless baking than traditional duct work. They can also travel with operators as foodservice operations grow so they don’t have to get left behind.

Ventless Fryers

The Wells Ventless Cooking System Fryer (WVA) is great for foodservice operations that are low on space but want to add more revenue-generating equipment to the kitchen. This high-production fryer has the narrowest footprint in the industry at about 16” wide and 76.5” tall, does not need any outside ventilation and has self-contained fire protection, allowing operators to fry almost anywhere.

All-in-one ventilation, fire-protection and fryer, Wells has everything you need for easy, ventless frying.

Features include:

- Automatic basket lift for safe handling

- Auto temperature controls to ensure even and consistent cooking

- Single, push-button repeat cycle timer

- Standard, paperless filtration system that helps reduce labor and helps keep oil clean

- Stainless-steel, low watt density elements provide longer oil life

- Available with digital or manual controls. Digital controls are easy to program

Wells Ventless Filtration Operation Tips

All hoods include filter indicators that turn on when filters need replacing or if the system is clogged. Maintenance is easy to perform and mostly requires the operator to change filters every so often. Buying a backup set of filters with each of these models will potentially save a lot of down time for operators in case of a malfunction.

Safety features:

- If filters are not installed properly, the system will read "check filter" error and won’t work.

- All ventless units have manual pull station, except for the canopy.

Browse all Wells ventless equipment here.

Ventless hoods can be vented outside of the space where they’re being used. This is significant in situations where the heat load is too much for the space, as Wells units do not eliminate heat load.

When purchasing any Wells ventless hood system, customers must complete a ventless approvals application for all equipment being placed underneath to ensure proper codes are met.

Please call our knowledgeable sales reps to start your ventless cooking operation today at 404-752-6715, ext. 2, or stop by our Norcross showroom.