Refrigeration Compressor Guide

Commercial refrigerators and freezers are the most important pieces of equipment in any restaurant or place where food and beverages are handled and stored. Experts say that refrigeration accounts for 10-16 percent of total energy consumption in the food service industry.

How do commercial refrigerators work?

Contrary to popular belief, a refrigerator does not actually keep food cold. It cycles hot air out of the unit and keeps the residual, cooled air at a temperature that is below the air temperature outside of the unit. The cooling of the items inside is a consequence of the refrigeration process.

This goes for equipment including worktop refrigerators, bar coolers, undercounter refrigerators, reach-ins and walk-ins.

ACityDiscount pros advise that if your refrigerator compressor uses less energy and runs smoothly, the more energy costs you will save over time. A compressor is a device that increases the pressure of a gas by reducing its volume. They are like pumps in that they can transfer fluid to other parts of the system through a valve.

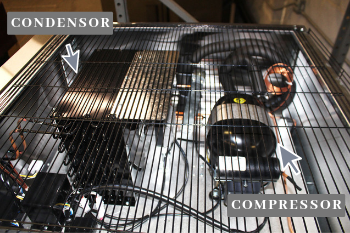

Consider your compressor as the “heart” of your refrigerator operating system, with the condenser and evaporator as the main arteries that pump the refrigerant (the ‘blood”) through the unit (or “body”) to regulate the temperature, keeping inside temperatures at a set point and cooling food as a result.

If the refrigerant does not properly absorb and release heat, due to a dirty evaporator and condenser coils, it forces the condenser to work harder to circulate air through the unit and disperse heat. This can lead to higher energy bills.

For refrigerators to run properly, the internal temperature must consistently stay at a point below the temperature of the surrounding environment. No refrigeration unit is airtight. Often, cold air leaks out and warm air gets in, causing the temperature to rise above its set point. When the inside temperature of a refrigerator/freezer rises above its set point, temperature sensors in the unit signal the compressor to kick on and the cooling process begins. Both walk-in refrigerators and reach-in refrigerators generally utilize similar refrigeration condensers and compressor types.

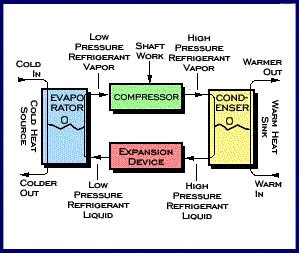

The cooling process is separated in four stages, based on the following diagram of the parts that make up the common refrigerator condensing units:

Evaporation : The evaporator takes in ambient warm air inside the refrigerator or freezer, and when brought in contact with liquid refrigerant, produces a vapor that is pushed to the compressor. The refrigerant is what helps absorb heat in the unit.

Compression: The compressor pressurizes the refrigerant, causing the vapors to condense even further, using an electric motor drive, and cools down the refrigerant further at the same time. The most common compressors are a reciprocating (piston and cylinder) or a screw (coil type).

Condensing: The refrigerant, now a high-pressured gas, enters the condenser. A heat transfer takes place, releases the heat and further cools the refrigerant, taking the refrigerant from a high-pressure vapor to a liquid.

Expansion: That “condensed” liquid is pushed to the evaporator through an expansion valve or tube. Since the refrigerant has been cooled through the condenser, the amount of refrigerant that needs to evaporate in the expansion valve is decreased (this process is called “flashing”). The cool air then enters the evaporator and more residual heat is released.

Once this process has taken place, the unit should reach its set temperature point and the compressor should stop running until more heat makes its way into the unit.

While there are different compressor types used in refrigeration and air conditioning, the most widely used in the restaurant business is a reciprocating or scroll compressor. Smaller reciprocating compressors are recommended for small walk-ins and reach-ins, while scroll compressors are a better option for larger units.

Here are the different compressor types used in refrigeration:

Reciprocating compressor: These are the most widely used in commercial refrigeration. They have a piston and cylinder, just like a car engine, and the reciprocating motion of the piston compresses the refrigerant inside the cylinder. A “hermetic” compressor just means that the housing has been sealed airtight.

Screw Compressor: Screw compressors are a type of rotary (circular) compressor, except they can produce a high amount of pressure with a small quantity of gas. They are made of a screw motor system with two meshing screws where the refrigerant gets compressed. These are mostly used for industrial refrigeration applications in factories.

Scroll Compressor: This compressor technology is made of two interwoven scrolls that compress or pressurize refrigerant. One of the scrolls is fixed and the other orbits the fixed piece without rotating. Small gaps are created when the scroll is in motion and that is where the refrigerant gets compressed.

The scrolls have different spiral shapes such as the Archimedean spiral (or the mathematical spiral), Involute motion (which is more circular like the way gears turn) and a hybrid, curve type of motion.

Since scroll compressors have fewer moving parts than the usual reciprocating types, they do not break down as much and will last longer in commercial kitchens. Scroll compressors are generally known to save energy costs over time and use 10-30% less energy than reciprocating/hermetic compressors.

One of our top selling brands of refrigeration, Nor-Lake, uses Copeland scroll compressors for their walk-in refrigeration units, which are proven to reduce energy usage by 10-30%. The diagram below shows a breakdown in savings using a scroll compressor compared to a reciprocating compressor for walk-in refrigerators and freezers.

How do I know when my compressor has gone bad?

Unit is not cooling: There could be a compressor leak or there is a part of the compressor that has stopped working. For example, a compressor will hum, but nothing is happening, which most likely means that the heat pump in the compressor has stopped working.

Short cycling: The unit will run for short periods of time, or you can hear the refrigerator running for 3-5 minutes or a few seconds at a time and then it shuts off. This is an indication that parts need to be replaced or the compressor is showing signs of wear.

Continuous or prolonged cycling: The refrigerator cycles on for hours at a time (continuous noise) and does not shut off. It’s most likely that it isn’t reaching the appropriate temperature.

Can I fix my own compressor?

The pros at ACityDiscount strictly advise against individuals (restaurant staff, management, etc...) removing or trying to fix refrigerator compressors themselves. Hiring a qualified HVAC technician to assess any refrigerator issues is the best way to go.

Why?... The refrigerant used in compressors is considered a hazardous material and some may contain greenhouse gasses that deplete the Ozone. The EPA closely regulates refrigerant used for commercial applications, such as in reach-in coolers, walk-in freezers, and other HVAC systems.

R290 is the most popular refrigerant used in foodservice nowadays. It is a hydrocarbon (HC) refrigerant that is non-toxic and does not contain ozone depleting properties, and it can help to reduce energy costs.

Ways to keep your condenser working at optimal efficiency:

Clean your refrigerator or freezer condenser coils regularly. Cleaning off dust and debris will help your condenser “breathe” better . The industry standard is every 90 days, but if your establishment experiences increased traffic during certain periods, it would be best to clean more often.

Here are some simple steps to cleaning your condenser coils:

- Unplug the refrigeration unit.

- Locate the condenser coils. Refrigerator condenser coils are usually located behind a grate at the front top, the bottom or at the back of the unit.

- After removing the grill plate, use a sturdy brush to lightly brush the dust from coils and fan. You can also use a vacuum to remove the dust as you brush.

- Vacuum the surrounding area and floor under fridge.

- Clean the grate or grill cover plate and re-attach.

- Plug in and use.

By allowing your system to continuously take in and release heat without restrictions, the compressor does not need to work as hard so you can keep your energy costs down.

A cooler or freezer is only as good as its parts. Make sure you are using the best parts that fit your refrigeration needs. The pros here at ACityDiscount are willing and ready to help you through the first-time buying or refrigeration upgrade process. Stop by our Norcross, GA showroom or give our sales team a call today at 404-752-6715.

Did you enjoy this article?

Subscribe to stay up to date on industry news and receive exclusive sales and promotions.