Everything you need to know about stainless steel care

My steel is stainless. Why do I need to maintain it?

Stainless steel is a staple in commercial kitchens. It is a durable and easy-to-care for metallic surface that, if cleaned and maintained properly, can stay shiny and looking like new for years to come; what’s more, cleaning and maintaining your stainless steel is easier than you might think.

Read on for the best tips to keep your cookware, equipment and utensils looking like new.

First, we must understand the properties of stainless steel and what causes corrosion and deterioration. Basically, what causes your stainless steel to rust and stain.

Stainless steel is a steel alloy containing iron, chromium and nickel, with a minimum percentage of 10.5% chromium content that forms a protective film to keep the metal corrosion-resistant with little maintenance, unlike iron or regular steel that easily corrodes. The percentage of iron in any stainless steel material (about 70-80% in kitchen grade steel) makes it capable of rusting under certain conditions.

Keeping this film intact using maintenance and cleaning best practices will help you keep your equipment in great condition, longer.

The main series of stainless steel used in foodservice equipment include:

Austentic Stainless Steel: 200-300 Series is used in over 70% of stainless steel production. It has a face-centered cubic crystalline structure which means its molecules have multiple points of attaching to one another which gives it structural strength but also flexibility. This type of stainless steel is created with chromium and nickel in varying degrees which further divides the type into common types such as 304 (18% chromium & 8% nickel), 316 or marine stainless steel (one of the most common in foodservice), and 18/10 (18% chromium & 10% nickel).

Austentic stainless steel can be polished to mirror finish, is non-magnetic, maintains structure at high and low temperatures, and is extremely corrosion resistant.

Flatware is typical made of 18/10 austentic stainless steel. Foodservice Work Tables are often made of 316 series stainless steel.Generally more expensive due to its corrosive resistance.

Ferritic Stainless Steel: 400 series has a much lower chromium and nickel content than austentic. It can be classified in grades such as 18Cr-2Mo, 26Cr-1Mo, 29Cr-4Mo, and 29Cr-4Mo-2Ni, based upon the alloys of chromium in its composition.

Ferritic stainless steel does have some corrosive resistance and can be polished, but has limited temperature range before its structure is weakened. It is also magnetic properties thanks to its body-centered cubic structure.

Martensitic Stainless Steel is extremely strong and tough especially after tempering or heat treatment. You can see martensitic stainless steel in items such as pocket knives. It contains 12-14% chromium, less than 2% nickel, and less that 1% carbon.

Martensitic stainless steel is magnetic and is often used for medical instruments or lightweight precision tools.

So, what causes corrosion?

Corrosion can develop on stainless steel equipment if the passive film has been broken down due to mineral deposits from hard water, use of harsh cleaning tools, cleaners containing chloride, food particles that have been left behind and salt.

Over time, these causes create tiny pits and cracks on the surface of the steel (unseen to the naked eye) that increase in size and depth over time, resulting in the typical red-orange rust.

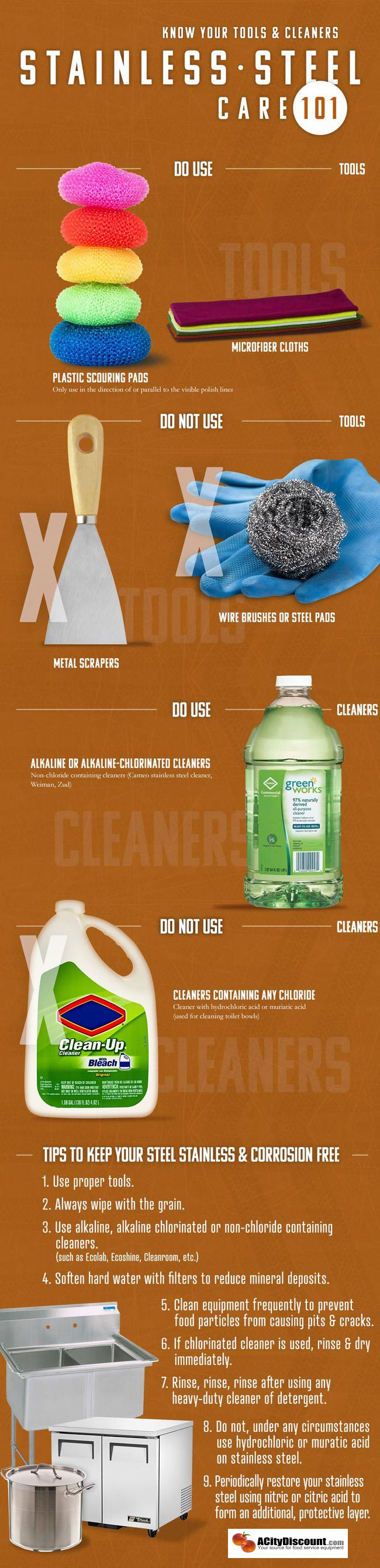

Here are some quick tips to help prevent your stainless steel from corroding.

How do I remove rust on my kitchen equipment?

Rust spots can still occur even after continued cleaning and care of your equipment. You can take these steps to help restore the look and shine of your stainless steel.

- Find the root cause. Whether it be mineral deposits, hard water, a mechanical abrasion or chlorides and chemicals, determining the cause of the corrosion is important so you can correct any mistakes and avoid further corrosion of your equipment.

- Use a scratchless pad, like the Scotch Brite cleaning pad from BK Resources, to remove rust or dull scratches on your equipment. Always rub gently in the direction of the grain of the steel and do not use water, just the pad on the metal.

- Use a cleaning paste (like Bar keepers Friend ) with a soft cloth or microfiber pad and apply to the affected area.

- Use another area of the same cloth, dampened with water, to remove excess paste.

- Follow the cleaning step with a stainless-steel polish to restore the “passive” layer and remove any lingering corrosive elements. You may need to wash any food-contact surfaces after completing this step.

How do I keep my stainless-steel cookware rust free?

- Always add salt to boiling water or hot liquid to dissolve it. Direct contact with salt can cause pits to form in the protective coating.

- Use plastic, silicone or rubber utensils with stainless cookware, anything else will damage the surface.

- Cookware will generally last longer if washed by hand and not in the dishwasher, using hot soapy water. Again, scrub in the direction of the metal grain.

Stainless steel actually thrives with frequent cleaning, and, unlike some other materials, it is impossible to “wear out” stainless steel by excessive cleaning.

| Job or Use | Cleaning Agent | Tip |

| Routine cleaning | Warm Water, Soap, Ammonia, 'Safe' Detergent | Apply with soft cloth or sponge. Can be used on all finishes. |

| Remove Fingerprints or Smears | 3M Stainless Steel Cleaner and Polish, Arcal 20, Lac-O-Nu, Lumin Wash, O’Cedar Cream Polish, Ecoshine | Use microfiber cloth for “streak-free” finish |

| Stubborn Stains | 3M Stainless Steel Cleaner and Polish, Allchem Concentrated Cleaner, Cameo Copper Cleaner, Liquid Nu Steel, Copper’s or Revere Stainless Steel Cleaner, Household Cleaners, Lumin Cleaner, Zud Restoro, Copper-Brite | Rub lightly using damp cloth in direction of polish lines or grain. |

| Grease & Fatty Acids, Burnt-on or Baked-on Foods | Easy-Off, De-Grease-It, 4% to 6% hot solution of agents such as tri-sodium polyphosphate, 5% to 15% caustic soda solution | Excellent removal on all finishes. |

| Restoration, Passivation | Benefit, Super Sheen | Per instructions |

To learn more about how to prevent corrosion, contact your equipment manufacturer or visit their website or your cleaning materials supplier. If you are experiencing any issues with equipment bought though ACityDiscount, please contact us at 404-752-6715, Monday-Friday between 8:30am-5:30pm and Saturday between 10am-3pm.