In the food service industry, ways to work more efficiently are always on the horizon. From a time-saving work process, to an auto feature on an equipment piece that works by itself – innovative breakthroughs in the restaurant industry continue to simplify workloads, save money, and save time. This guide will provide specs for cutting edge equipment that will improve the way you and your staff works.

Turbo Air Refrigeration

Turbo Air made waves when they manufactured many lines of refrigeration with a self cleaning condenser. Though the concept was developed by Structural Concepts, Turbo Air adapted the idea and applied it to nearly their entire line of products and rolled it out at no price increase, making it standard even on entry level models. High volume restaurants create a lot of dust which can prevent the condenser from properly releasing heat which is what makes the self-cleaning condenser an attractive feature.

Features/Usage/Maintenance

- Uses a rotating brush to catch dust 2-3 times a day during defrost cycles.

- Dramatically improves energy efficiency by lowering consumption cause by a dirty condenser.

- Increased life span

- Decreased power usage

- Minimize or avoid compressor failure and health inspection failure

- Avoid manufacturer warranty becoming void

Turbo Air customers can enjoy full warranty coverage for 3 years of standard warranty period, without worrying about cumbersome maintenance requirements on the condenser.

Vulcan CEF Series Fryer

If space has been a concern for you with fryers, perhaps a Vulcan CEF Series Fryer is your next investment. The Vulcan's CEF fryer has all the benefits of a traditional electric floor model, but offers a convenient and space-friendly countertop design.

Standout feature & other features

- Ribbon style heating elements create maximum surface area for quick recovery and swing up for easy cleaning

- Designed to be paired with a refrigerated or freezer base for workflow optimization 17 kW elements on 40 lb. model and 24 kW elements on 75lb. model

- ENERGY STAR® certified 40 lb. model only(75 lb model, though not energy star is available and is the first electric countertop fryer in its capacity) - See more at: http://www.vulcanequipment.com/Products/CEF-Series-Electric-Countertop-Fryer/#sthash.wU7QfbD1.dpuf

Cleaning/ Maintenance

Before any food preparation, thoroughly wash the protective oil from all surface parts and the tank interior with hot soapy water to remove any film residue and dust or debris. Do not use chlorine or sulfate/sulfide cleaners.

- Wash any accessories shipped with unit.

- Rinse fryer and accessories thoroughly and drain the fryer.

- Wipe tank completely dry with a soft, clean cloth.

Robot Coupe CL55 Workstation

The Robot Coupe is designed to meet the needs of chefs seeking solutions to serve large amounts of fruits and raw vegetables. With higher production capacity, cooks can now provide attractive and original cuts to present fresh fruit and vegetables in a more eye-catching, high-volume way. The Robot Coupe CL55 Workstation is ideal in institutional settings with very high demand, such as prisons, schools, hospitals, and others.

Features/ Benefits

The CL55 model can be fitted with an automatic feed-head for volume processing and cut quality. The design of the automatic feed-head gives a larger introduction capacity and therefore bigger outputs.

- The tube is used for continuous feeding of long or fragile fruit or vegetables.

- Robust construction for commercial kitchen use.

- Ergonomics

The optional Stainless Steel mobile stand gives the perfect operating height and accepts standard size gastronorm containers allowing you to prepare large quantity’s with the minimum of fuss.

Output -This model is equipped with a pusher feed- head (area: 6 7/8«) including a feed tube (Ø 2 5/16 ») and a stainless steel movable stand. The shape of the pusher has been conceived for a better use comfort and for fast processing.

Usage

The Robot Coupe CL55 Workstation can be used for a variety of slices such as cucumbers, tomatoes, and pickles. Now, you can create ripple cuts, and grate food items with ease and efficiency. The CL55 model also dices, allowing more versatility in your food prep!

Cleaning

The CL55 comes with a removable bowl and lid for easy and perfect cleaning. All parts which come into contact with foodcan easily be removed for cleaning, thus maintaining the highest standards of hygiene.

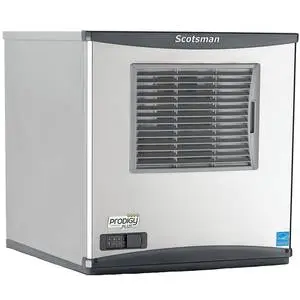

Scotsman Prodigy PLUS!

Prodigy PLUS self-monitoring ice machine is designed with external indicator lights which constantly communicates the machine’s operating status for complete confidence in its ice-making capability.

Features

- AutoAlert™ indicator lights – Innovative LED lights, letting you know up-to-date operating status operating status, such as when it is time to descale, sanitize and more.

- WaterSense – The patented WaterSense reduces scale buildup, extending time between cleanings.

- Smart-Board™ – An optional advanced feature, Smart-Board provides NAFEM data protocol and additional operational data that can be displayed on-screen or transmitted remotely, resulting in early alert and fast diagnosis of operating issues.

- Vari-Smart™ – An optional Vari-Smart ultrasonic ice-level control sensor enables you to program ice levels for up to seven days in advance, keeping just the right amount of freshly made ice in the bin.

Usage

From supermarkets to convenience stores and a variety of operations in between, flake ice is greatly preferred for its small size and soft texture. This type of ice is great for displaying fish and produce. Available with the innovative Prodigy Plus self-diagnostic technology, this line of flake ice machines delivers the highest level of performance, whether you’re keeping salad bar items crisp, chilling soft drinks on display or blending mixed drinks.

Cleaning/ Maintenance

With its built-in antimicrobial protection, this unit ensures safe, clean operation, with a removable door and top that provides ample access to internal components, so they’re always easy to service and clean.

Moffat Ovens

Turbofan convection oven systems by Moffat are the product of careful study of the convenience markets to offer improvement in functionality in a reduced overall footprint.

- Moffat E32D5 = 920.4 cubic inches

- “Brand B” = 1410.5 cubic inches

Features/ Benefits

- Two speed bi-directional fan systems, which achieve better than ever even-bake results.

- A twin bi-directional reversing fan system (the E28D model).

- Redesigned high performance fan and fan motor.

- An expanded line of models and tray capacities suit any application, with 2-5 tray capacities in half pan size ovens, 3-5 tray capacities in full size ovens.

- Portable cooking. Choose from the E22, E23, E27 or E31 and simply plug it in and go

- Porcelain enameled oven interiors.

Usage

Perfect for baking and cooking in food service establishments such as cafés, convenience stores, chain bakeries, service stations, and many other types. Its versatility allows usage with frozen goods, Danish pastries, meat loaf, casseroles and more!

To Turn ‘On’ the Oven; - Rotate ‘Temperature’ Control (2) from the ‘Off’ position. ‘Power On’ Indicator light (1) illuminates.

To Set the Temperature; - Rotate ‘Temperature’ Control (2) to the temperature required. ‘Oven Heating’ indicator light (3) will remain ‘On’ until the oven is up to temperature.

To Load the Oven; - open the oven door and load product. Avoid delays in loading the oven as this will delay the oven’s temperature recovery.

To Set the Timer; - Rotate the ‘Timer Control’ (4) to the required time.

Cleaning

The plug-in design makes cleaning and replacement quick and effortless.

- Undo and remove the rack securing screw securing the front of the RH side rack.

- Lift up and unhook the rear of the rack from the locating peg at the rear of the oven.

- Tilt the top of the rack inwards and lift the rack off the lower mounting brackets.

- Lift the LH rack off the front locating peg.

- Pull the rack forward out of the oven to disengage the rear of the rack from the rear location peg and remove the rack from the oven

- Clean the racks with a mild anti bacterial detergent and hot water, using a soft bristled brush. d. Dry the racks thoroughly with a dry cloth.