Frying oil is the lifeblood of many restaurants, but with oil prices sky high and labor an increasingly difficult issue, some owner-operators may not have done enough to create an oil management program that decreases costs and increases brand consistency and employee happiness.

Getting the best returns on oil investment and fried food costs is critical to sustaining your foodservice business. While most organizations have some form of procedure to track basic oil spending and handling costs, there’s still lots of room for error.

The rising cost of oil

The current supply chain shortages have been well documented, as well as the subsequent rates of inflation that are driving up prices in all sectors of the economy. Foodservice isn't immune, as we have seen increases in the costs of raw materials, manufacturing, and even the food supply.

Whether it's greater expenses or the decreased supply, both affect your bottom line. Yes, there is a shortage and higher cost for chicken wings, but those higher costs go well beyond the items getting mainstream press. In fact, there are even rising prices for the oil used to cook those wings.

Toss in the current supply chain issues plaguing the nation due to stalled seaports and a lack of truck drivers to haul critical produce and meats. This is leaving even large chain restaurants struggling to fulfill food for their menu offerings and sourcing items like paper bags for takeout.

According to Business Insider, the value of cooking oil has increased so much that restaurants and other types of foodservice operations are stockpiling oil to buy it at cheaper prices. Some are stretching the use of their existing oil, so it lasts longer with more frequent filtration becoming a tactic used to extend the life of frying oil.

Outside the restaurant, near the dumpster next to the parking lot, thieves are stealing used frying oil receptacles and are reselling them to be recycled into diesel fuel. Because the price of oil has increased 80 percent over the last year, this is a very lucrative transaction with some restaurants losing tens of thousands of dollars while thieves make around $1,500 per day.

8 Ways to Save Money on Frying Oil

- Make oil Last Longer

Operators who make all the efforts to extend the life of frying oil will ultimately save money, especially now when frying oil is so expensive. From filtering schedules to proper filtration, making oil last longer is the ultimate goal.

- Filer oil automatically

With automatic filtration or built-in filtration systems, operators can manage oil more efficiently. In an era when staffing is so scarce, anything that makes the job easier and safer is a great benefit that will ultimately save money in the long run.

- Save on labor

As we just mentioned, labor is in high demand. Many foodservice lifers are opting out and are choosing other professions. So how can operators decrease staffing demands while also saving on labor costs? For starters, make the frying oil management process as easy as possible.

- Reduce Risks

Frying oil programs are typically some of the most dangerous processes in commercial kitchens. To help mitigate these risks, frying oil management that is concise, scheduled, or even better, automated, will go a long way toward reducing safety risks in the back-of-the-house.

- Maintain Quality

What about the front-of-the-house? The reality is bad frying oil will turn food quality in unwanted ways. Clean oil leads to aromas and flavors that customers desire. Bad oil doesn't. Return visitors help operators make money, while returned food does not.

- Ensure better fryer controls

How can you ensure fried foods are cooked consistently and with quality? With a fryer that offers accurate controls. Fryer design that incorporates precise control allows operators to consistently cook foods at precise temperatures, and temperature is the key to cooking.

- Consider a waste oil management system

Thinking of your used oil as a profit point isn't a common thing, but with a waste oil management system, that is exactly what it can be. Who would not want to sell used oil and turn it into a little dough?

- Reduce the volume of oil

The less oil you use, the less an operation will spend on oil. With the instability in frying oil prices these days, finding a fryer that operates with reduced oil volumes can be a gamechanger for reducing overhead.

Save on labor

What is on the menu is not the only factor that can make or break a foodservice operation. Labor also plays a sizable role in your restaurant’s success. The restaurant industry is no stranger to labor challenges, but as more restaurants gear up to operate at full capacity once more, businesses must now contend with constraints in staffing and the labor considerations that come with those restrictions.

For labor-constrained kitchens, any innovation that makes the frying process more manageable while reducing the amount of labor needed is always welcome. Good help may be hard to find, but a good frying system can ease the burden on your existing kitchen staff with its versatile commercial deep fryers.

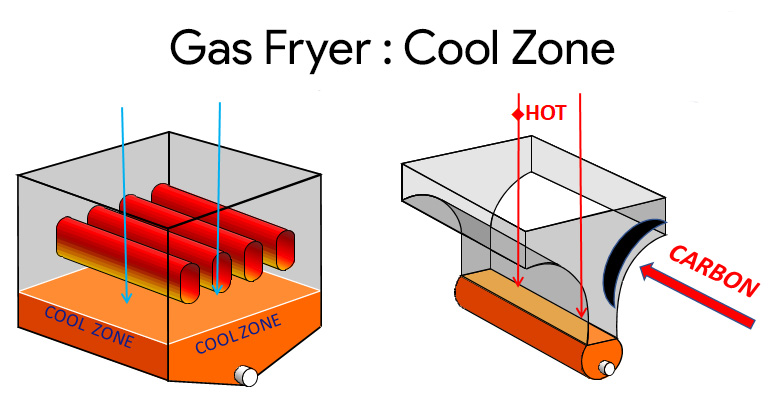

Gas Fryers: Cool Zone

Another way to keep oil fresh longer is to maintain a larger cool zone. This area is larger area for particulate and reduces flavor transfer. This also prolongs the life of the oil because 20% of the oil is always below 200 degrees in the bottom of the take, below the hot tubes. A larger cool zone results in significant reduction in carbonization, flavor transfer and oil breakdown. While fryers with smaller cool zones have a cool zone limited in size by the shape of the tank design and the burner placement.

ACityDiscount proudly partners with the best restaurant equipment brands available today, and we are proud to carry the best in commercial fryers.

To speak to a product specialist in the restaurant supply industry who can discuss which commercial fryer is best for you, call 404-752-6715.