What comes to mind when you think of a knife – is it safety, convenience, sharpness, grip, or construction? Honestly, each of these areas of interest should be a part of your decision process when choosing the proper knife for your food services. Selecting the proper knife, as well as understanding how to keep the lifespan of it is important for getting the most out of this nifty kitchen tool. This guide will help you in choosing knives for your restaurant or other foodservice establishment.

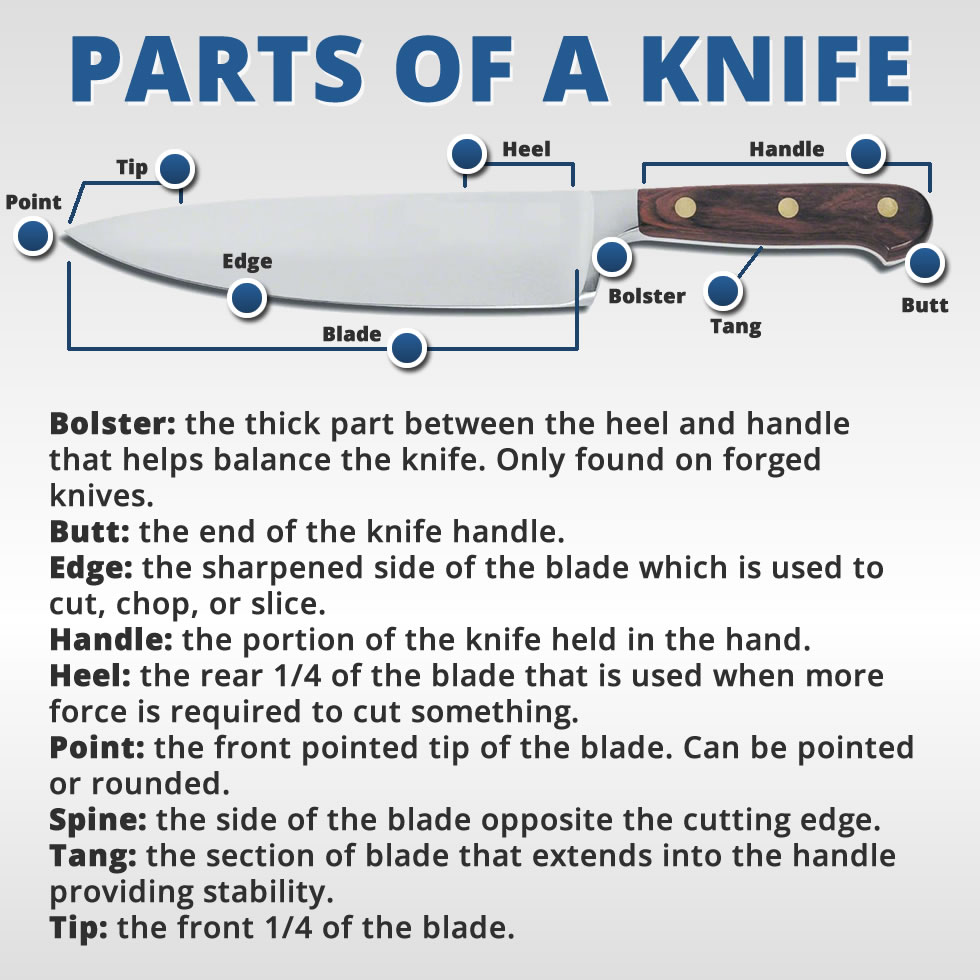

Parts of a Knife

Types of Knives

- Chef’s Knife: typically an 8 inch long knife, the chef’s knife is known as the workhorse of the kitchen. It is used for chopping, slicing, and dicing a variety of food.

- Utility Knife: used as a multipurpose knife, but is great basic cutting of fruits & vegetables. Most times, utility knives have scalloped edges.

- Paring Knives: small general use knives. IThey are great for cutting fat from meat and peeling potatoes. The handle is useful for smashing garlic and similar items. The standard will have a 3 – 4 inch blade. A bird’s peak paring knife is perfect for cutting or peeling round fruits and vegetables and resembles a bird’s peak as the name suggests. There are many varieties of these small blades.

- Mincing Knife: also called a mezzaluna or chopping knife, this tool is used for chopping herbs into smaller bits. It’s “U” shape allows for a rocking motion that gets herbs finely chopped. Typically, the seasonings made from the mincing knife can be used for soups and other dishes.

- Steak Knife: specialized knife used for cutting steak. The steak knife can come with a straight, hollow, or serrated edge.

- Bread Knife:equipped with a sharp edge and teeth, this knife makes it easy to cut bread apart in a clean slice.

- Carving Knife: popular tool in the kitchen during the holiday season, this knife is commonly used for carving large roasts and poultry. This type of knife is likely to be used at a carving station n at a buffet style restaurant.

- Filet Knife: has a thin, flexible blade made for the purpose of filleting fish.

There are many other types of knives that are useful in in specific situations; think butcher knives, boning knives, cleavers, oyster knives and more.

Grip

To make your knife using experience a safe one, you must consider grip, which can be determined by factors such as size, shape weight, and length. The way a knife fits in your hand is a big deal, and it is not safe for one to assume it is a one size fit all decision.

Pay attention to length of the blade as well as size of the handle. Matching your knife to your hand size will help reduce safety hazards, muscle fatigue and potential for carpal tunnel while increasing the effectiveness and efficiency of your knife skills.

Additionally, the way you hold a knife is very imperative. Make sure that your fingers are tucked away from the blade and your grip is secure.

Knife Construction

A deciding factor for selection a knife is the construction, which consists of the knife’s appearance, and functionality. These features mainly include the handle, the blade and the tang.

Blade

The blade of a commercial knife is usually made with stainless steel; leave the ceramic knives for home use. The most common types of stainless steel used are 420HC, 440C and VG-10 stainless steel. Japanese knives are usually made of VG-10 as it is high-carbon stainless steel that retains a fine edge for a long time.

The edge of the blade is just as important if not more so than anything else about your knife. There are 4 main type of edges:

- Straight edge: also known as flat ground, is the most common type of blade edge. It is made by grinding the edge in a straight line to taper it to a sharp wedge. Usually the very bottom of the blade is the only part sharpened.

- Scalloped edge: also known as serrated edge or wavy edge. This edge features teeth like points along the edge with curved indentations between. These are great on bread and fruit knives.

- Granton edge: these blade feature hollowed out portions on the flat side of the blade. This helps when splicing thin portions as it allows the product to slide off the knife easily.

- Hollow Edge: made by grinding the blade front near the midpoint to the edge of the blade which makes for very thin cutting edge. These are fantastic for delicate skinning, peeling or delicate design work.

Tang

The tang of a knife comes as a full tang, partial tang, rat tail tang, and encapsulated tang. The length of your tang oftentimes determines the strength of your knife.

- Full tang: Extends from the tip of the blade to the grip, and affords added leverage. This tang has the most amount of steel and therefore is less likely to bend out of shape. The downside is that it makes the knife heavier, so a light-handed person may not feel comfortable with this choice.

- Partial tang: Narrow, and only extends partially in the handle.

- Rat tail tang: Narrows as it goes through the handle and is either threaded at the end or welded to a piece of threaded rod.

- Encapsulated tang: Has the handle piece molded around it and fastened into place.

Handle

Knife handles come in different materials:

- Wood handles: Long- standing, wood has been used for handles for years. Wood is attractive, diverse, inexpensive and comfortable. However, it can become too absorbent over time.

- Stainless Steel handles: A heavy material that is very durable, and often combined with rubber to curve its slippery feel.

- Aluminum handles: A strong, light, yet durable material but may become slippery.

- Plastic handles: Tremendously strong, yet lightweight. These handles are very durable and easy to clean. There are a many types of plastic used for knife handles including resin, polypropylene, nylon, and polyoxyethylene.

Safety & Maintenance

Knife care will extend the lifespan of your knives, allowing you to enjoy your tool longer and to its full potential. Many of the same aspects affect both safety and maintenance. To ensure safety and maintenance, a few best practices include:

- Avoid placing knives on the edge of counter tops where they can be brushed or grazed against accidentally.

- Use wooden, bamboo, or plastic cutting boards when possible as granite and glass can be damaging to a knife.

- Never put knives in the dishwasher. Dishwasher chemicals are often harsh on utensils, and can result in a dull knife.

- Store your knife properly. A knife rack may help you preserve and store you knives safely.

Sharpening

Sharpening your knife is both a part of safety and maintenance. Using a dull knife can be dangerous, as a dull knife can easily slip off items instead of cutting through it as intended, yet it is still sharp enough to cut you. Using a dull knife causes you to use more force than you would have to otherwise, and that’s risky business. You can sharpen your knife using different types of sharpening tools :

- Stone Wheel

- Steel

- Diamond Stone

Tip: Make this process easier by using steel that is easy to sharpen. Soft steels will be easier to manipulate, and are less prone to chipping and breaking.

No Knife Strife

If you follow these guidelines, you will have the basics of choosing the proper knife for your food prep needs, safety, maintenance, and applications. Your commercial kitchen will run smoother when you have the proper tools to get the job done. Having a good understanding will also help you stay sharp and get back to focusing on other priorities in your food service establishment.