ACityDiscount experts: invest now, save plenty later with high-efficiency deep fryers

Fried foods are the greatest – from French fries, fish and blooming onions to mozzarella sticks, tempura and of course… fried chicken! The aroma, the crunch, the taste keeps customers returning. Meanwhile, foodservice operators – restaurants, food trucks, caterers, etc. – attempt to capitalize on fried food popularity by keeping costs low (especially oil costs) and investing in the best commercial deep fryer. What should you buy? We have answers! (Hint: cheaper is not always better. In fact, it’s often more expensive.)

Energy Efficient deep fryers vs. heavy-duty deep fryers: Which deep fryer is a smarter investment?

Which is the smarter (as in less-expensive) long-term investment?” It’s one of my favorite questions to ask shopping chefs and restaurant owners in search of commercial deep fryers. Most people glance at price tags in our Atlanta-area showroom or browse ACityDiscount.com. Overflowing with confidence, they say economy deep fryers.

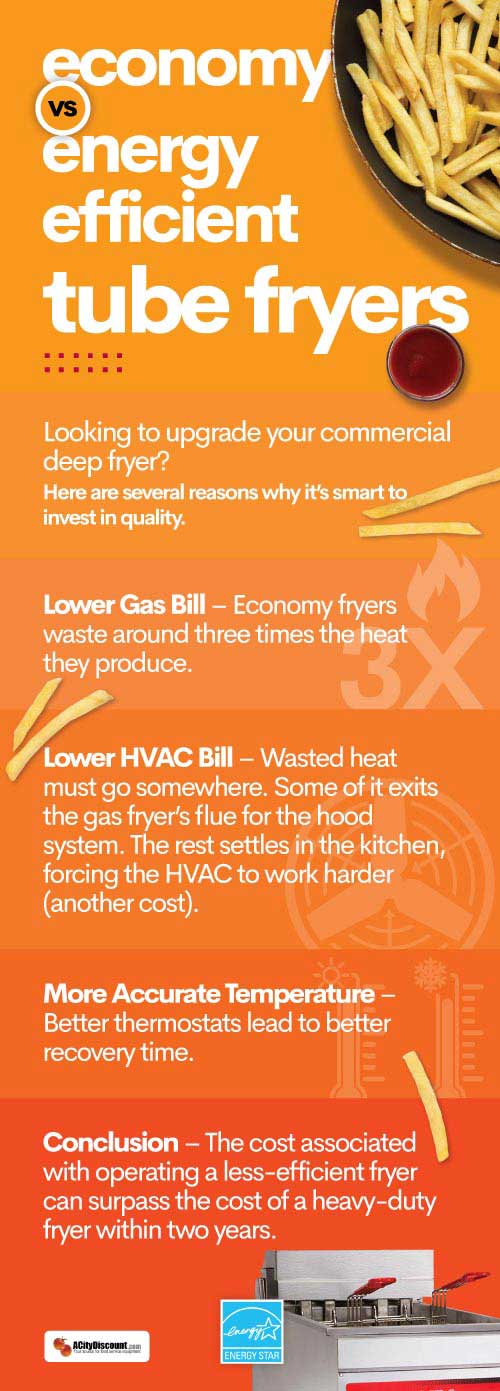

Sorry guys; wrong answer. The correct answer is (insert drum roll) high-efficiency fryers. While economy gas fryers cost less than high efficiency units at the time of purchase, related costs add up quickly after purchase, making high-efficiency fryers more desirable. I’ll explain.

The optimal cooking temperature for gas fryers - also known as tube fryers – is approximately 350 degrees. Yet on economy fryers, the area in the back of the fryer where heat exits – the flue – may exceed three times the temperature of the oil. That's three times (or more) of wasted energy – energy costs that show up on monthly electricity and gas bills. That’s why it's less important how many BTUs a unit can push out as opposed to how much energy it actually utilizes. What good are BTUs of 100,000 if you can’t use all that heat? Most of that wasted energy heads to your hood system. The rest settles in your kitchen, creating a rarely-calculated deep fryer expense: the cost of running your HVAC longer and harder to cool off a hotter commercial kitchen. All this wasted energy means fried food profits are literally flowing out the back of your economy gas fryer.

"Within months of purchasing an economy gas fryer, high-efficiency fryers – armed with higher energy efficiency – start to look like cost-saving options," said Krista Haynes, showroom sales lead at ACityDiscount. "That’s why many of my returning customers invest in high-efficiency gas fryers. They experienced the cost of creating fried foods with the economy line and realized it’s more than the initial investment… don’t forget the daily costs!"

Pick a Frymaster fryer

Let’s compare three high-efficiency commercial deep fryers by Frymaster. Each floor fryer suits a specific foodservice need – depending on budget, back-of-house skill level and expected usage. Energy Star rebates are available for many of these units. For details, ask an ACityDiscount team member.

Frymaster Tube Deep Fryer

Pick a Frymaster fryer

Let’s compare three high-efficiency commercial deep fryers by Frymaster. Each floor fryer suits a specific foodservice need – depending on budget, back-of-house skill level and expected usage. Energy Star rebates are available for many of these units. For details, ask an ACityDiscount team member.

Tube (Gas) Fryer

Best option for fried foods with high water content (fresh cut fries) and high sediment (wet batter, fried chicken). Easy insulation.

Open Pot Gas Fryer

Optimal for freezer to fryer products (medium sediment). Easy to clean. Less oil dedicated to cold zone.

Open Electric Fryer

Utilized for medium to high sediment items. Fast heat recovery and more accurate cooking temperature. Greater initial investment (unit and installation). Consult with your local power company before installation.

Key terms to learn about commercial deep fryers

- Frying area - The amount of space available to fry products (length x width).

- Fryer battery - A set of fryers banked together, frying independently, but utilizing the same gas connection and/or oil filtration.

- Tank capacity - The amount of oil a deep fryer can hold. For example, a Frymaster SR142G Dean 43lb Super Runner Gas Deep Fryer (105,000 BTUs) can hold 43 lbs. (21 liters) of oil.

- Output - Level of hourly production. Expect a 40-lbs. Frymaster fryer to produce 1-1/2 times its product weight an hour (approximately 40-60 lbs).

- Recovery time - Length of time it takes for oil to return to desired cooking temperature after frozen, fresh or breaded foods are submerged. If the temperature drops too far or fails to recover quickly, foods will absorb excess oil, altering taste. And nobody likes greasy food.

- Temperature range - Optimal level of heat to create amazing fried foods. Frymaster recommends about 350 degrees.

- Cook time - Amount of time it takes to transform fresh, frozen or breaded foods into fantastic fried feasts! Times vary depending on food items, as well as temperature of items before they are dropped in fryer.

- Flue - Area behind gas fryer where gas travels out of the unit and toward the hood.

Oil filtration

What’s the most expensive aspect of deep frying?

Hint: It’s not the deep fryer.

It’s the oil! Restaurant owners can expect to spend more than double the price of a deep fryer annually on oil.

Want to decrease this operation cost? Invest in oil filtration, which can double the life span of oil, while improving food quality – the key to repeat customers.

3 Ways to accomplish oil filtration

Cone Filtration - This style of oil filtration is the least expensive, yet the most labor intensive. Once cooking oil is cooled inside a deep dryer, it is drained into a container. The oil is then poured into a second container with an attached filter cone and cone holder to catch small particles.

Portable Filtration - Cooking oil is pumped through a hose from the deep fryer to this unit. After oil is filtrated, it is pumped back into the deep fryer.

Built-in filtration system - The oil filtration system is built into the deep fryers, so there’s less chance for employee injury during the filtration process. Recommended for large foodservice operations.

Which items break down oil?

- Water - Ice crystals from frozen foods and/or release of water from foods.

- Air - Exposure to air during cooking process and later during filtration and when fryer is not in use.

- Sediment - Food particles reach the cold zone and continue to cook, burning, thus changing the color of oil, degrading it.

- Heat - Cooking at higher-than-normal temperatures degrades oil.

Deep fryer accessories

Deep frying tips

- Don't overload fryer baskets.

- Keep temperature at 350 degrees or lower.

- Turn fryer down or off during slow periods.

Questions about purchasing the right commercial deep fryer for your restaurant or food truck? Give ACityDiscount a call at 404-752-6715 (ext. 2 for sales) or stop by our showroom in the Atlanta suburb of Norcross at 6286 Dawson Blvd, NE.